More about us

- Our Mission

- News

- FAQ

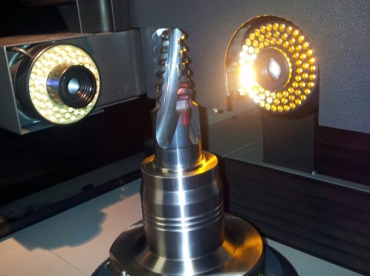

Simple, clear and precise! These are the qualities of the range of cutting tools for milling and threading that we offer our customers facing daily technical problems and seeking to improve their productivity.

Extensive experience in almost all fields of mechanics , many tests of cutting tools made of cemented carbide and with indexable inserts, a wide range of existing materials and a constant and careful testing, these are the ingredients of our success.

Mon 15 August 2016New website

New website of MPSA

What grinding machines do you use in your production?

Our fleet consists of machines of the brand Michael Deckel, all our machines are equipped with CAD Rototool system.

Do you produce special cutters for discs and turbines blades?

Yes. We have extensive knowledge in the gas and steam turbines market. We can offer "Christmas Tree" and "Onion" profiles. However, we have few restrictions on the width of the neck and tolerance between the shoulders.

Why don't you have a catalog?

According to statistics, most customers are looking for a customized tool with modified length and unique features. So rather than producing a thick catalog like our competitors, we have resolved to provide an assortment focused on the specific needs of each client. We will only offer our customers what they need.

Why did you choose the VHM rods produced by Extramet?

Extramet carbide monobloc rods are of superior quality. Their density prevents many errors inherent to the cutting process. In the field of advanced technology, the quality of the raw material is decisive in the design of impeccable pieces. MPSA works to ensure the success and profitability of its customers.

Do you have experience in oil pipe connections threading?

Yes. We work with the Russian leader seamless oil pipes: casing and tubing. To this end, we have developed, in cooperation with a European partner, a system of indexable inserts to improve the time and cost of production.

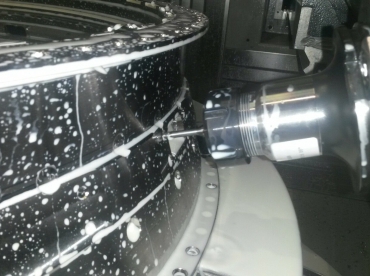

We have developed the "Fixed Parts Turning" technology that produces pipes, muffs and the other connected parts. The specificity of this method is that the pipe remains motionless and a mobile working head rotates around the it thus allowing greater quality of assembly and seal.

What's the delivery time of your tools?

Usually 3 to 4 weeks.

Our History

Established in 2012 in the canton of Vaud, Switzerland, Mécanique Privée SA (MPSA) is the new European chapter of a professional activity for more than 15 years in Russia.

Working on very demanding high level Russian markets such as aerospace, gas and steam turbines or high-precision motors, MPSA has managed over the years to transform and improve its tooling system.

Jointly with our European partners, MPSA provides solutions for every project considering not only the technical and quality aspects but also taking into account the economic needs of our customers.

In 2013, MPSA signs a partnership with Extramet AG whom becomes our preferred supplier of cemented carbide rods for cutting tools range from "Standard", "Modified" and "Special". Thanks to this collaboration, we offer quality products with optimized production time.

Since 2014 MPSA partners with world renowned thread specialist Xactform SA. This partnership allows us to renew our threading tools solutions and launch a the new FGP System (For General Purposes) making it the first choice to cover a wide range of applications.